浏览数量: 32 作者: 本站编辑 发布时间: 2024-11-18 来源: 本站

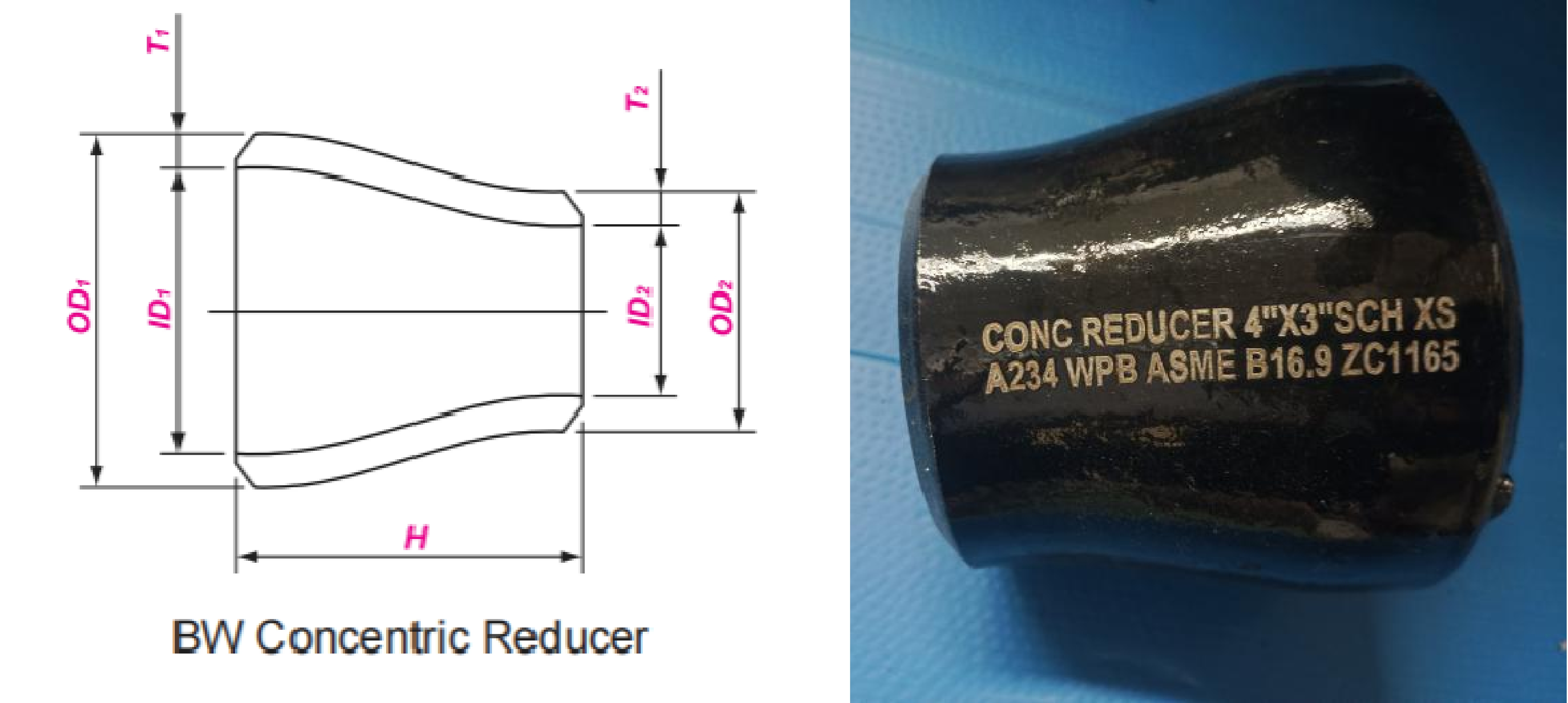

A234 WPB 同心大小头,是指圆心在同一条直线上的大小头管件。这种管件通常用于连接两种不同管径的管道,确保管道系统的流畅性和完整性。碳钢同心大小头的主要结构特征是同心,这种结构使得流体在流经大小头时,流动方向不会发生偏移,能够保持较为平稳的流动状态。

A234 WPB 同心大小头是按照美国材料与试验协会(ASTM)A234 标准制造的,其中WPB表示其材质等级。WPB材质是一种中碳钢材质,具有良好的强度和韧性。在常温下,WPB 材质的同心大小头可以承受一定的压力,适用于如给排水系统、一般的工业蒸汽或气体输送系统等。

A234 WPB 同心大小头的规格

Size Range | 3/4" - 60" / DN20 - 1500 |

Thickness Schedule | SCH 10 - SCH 80, SCH 160, XXS |

America Standard | ANSI / ASME B16.9 |

Japan Standard | JIS B2311/2312/2313 |

Germany Standard | DIN2605/2615/2616/2617 |

Europe Standard | EN10253 |

Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

ASME B16.9 同心大小头的尺寸

OD1 | OD2 | END TO END | SCH 40 WEIGHT |

NPS | NPS | H | KG |

3/4 | 3/8 - 1/2 | 38 | 0.07 |

1 | 1/2 - 3/4 | 51 | 0.14 |

1 1/4 | 1/2 - 1 | 51 | 0.19 |

1 1/2 | 1/2 - 1 1/4 | 64 | 0.29 |

2 | 3/4 - 1 1/2 | 76 | 0.46 |

2 1/2 | 1 - 2 | 89 | 0.85 |

3 | 1 1/4 - 2 1/2 | 102 | 1.11 |

4 | 2 - 3 1/2 | 102 | 1.8 |

5 | 2 - 4 | 127 | 3.05 |

6 | 2 1/2 - 5 | 140 | 4.35 |

8 | 3 1/2 - 6 | 152 | 7.12 |

10 | 4 - 8 | 178 | 11.8 |

12 | 5 - 10 | 203 | 17.8 |

14 | 6 - 12 | 330 | 34.3 |

16 | 6 - 14 | 356 | 48.3 |

18 | 8 - 16 | 381 | 65.3 |

20 | 10 - 18 | 508 | 102 |

22 | 12 - 20 | 508 | - |

24 | 12 - 22 | 508 | 143 |

26 | 12 - 24 | 610 | - |

28 | 14 - 26 | 610 | - |

30 | 14 - 28 | 610 | - |

32 | 20 - 30 | 610 | 230 |

34 | 22 - 32 | 610 | 245 |

36 | 22 - 34 | 610 | 282 |

38 | 24 - 36 | 610 | - |

40 | 28 - 38 | 610 | - |

42 | 28 - 40 | 610 | - |

44 | 32 - 42 | 610 | - |

46 | 34 - 44 | 711 | - |

48 | 36 - 46 | 711 | - |

52 | 40 - 48 | 711 | - |

56 | 40 - 52 | 711 | - |

60 | 44 - 56 | 711 |

对焊管件的公差表

对焊管件的公差 | |||||||||||||

公称尺寸Nominal Size | 所有管件1)2) |

| 3D 弯头 | 180 " 弯头 | 管帽 | 异径管 、 | 翻边短节 | ||||||

DN | NPS | OD 3) 4) | ID 3) |

|

| O | K | U | E, E1 |

| G | R | t |

15-65 | 1/2 -21/2 | +1.6 | ± 0.8 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 | 0 | +1.6 |

80-90 | 3-31/2 | ±1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 | 0 | +1.6 |

100 | 4 | ±1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 | 0 | +1.6 |

125-200 | 5-8 | +2.4 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 6 | ± 2 | 0 | 0 | +1.6 |

250-450 | 10-18 | +4.0 | ± 3.2 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 | ± 6 | ± 2 | 0 | 0 | +3.2 |

500-600 | 20-24 | +6.4 | ± 4.8 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 | ± 6 | ± 2 | 0 | 0 | +3.2 |

650-750 | 26-30 | +6.4 | ± 4.8 | ± 3 | ± 6 | --- | --- | --- | ± 10 | ± 5 | --- | --- | --- |

800-1200 | 32-48 | +6.4 | ± 4.8 | ± 5 | ± 6 | --- | --- | --- | ± 10 | ± 5 | --- | --- | --- |

1300-1500 | 52-60 | +6.4 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

1600-1700 | 64-68 | +6.4 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

1800-2000 | 72-80 | +6.4 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

碳钢对焊管件防腐工艺

对焊管件通常由A234 WPB 材质制成,在不同的环境中容易受到腐蚀。刷漆可以在金属表面形成一层保护膜,将金属与外界环境隔离开来,从而减缓腐蚀速度,延长对焊管件的使用寿命。

3PE是一种三层结构的聚乙烯防腐涂层。这种三层结构的设计充分发挥了各层材料的优势,实现了良好的防腐效果。

3PE防腐一般由3层结构组成:

●环氧粉末(FBE>100um)

●胶粘剂(AD)170~250um

●聚乙烯 (PE)1.8~3.7mm

环氧粉末是一种热固性粉末涂料,主要由环氧树脂、固化剂、颜料、填料和助剂等组成。环氧树脂是环氧粉末的主要成膜物质,它提供了良好的附着力、耐化学性和机械性能。

内容为空!