浏览数量: 67 作者: 本站编辑 发布时间: 2024-11-20 来源: 本站

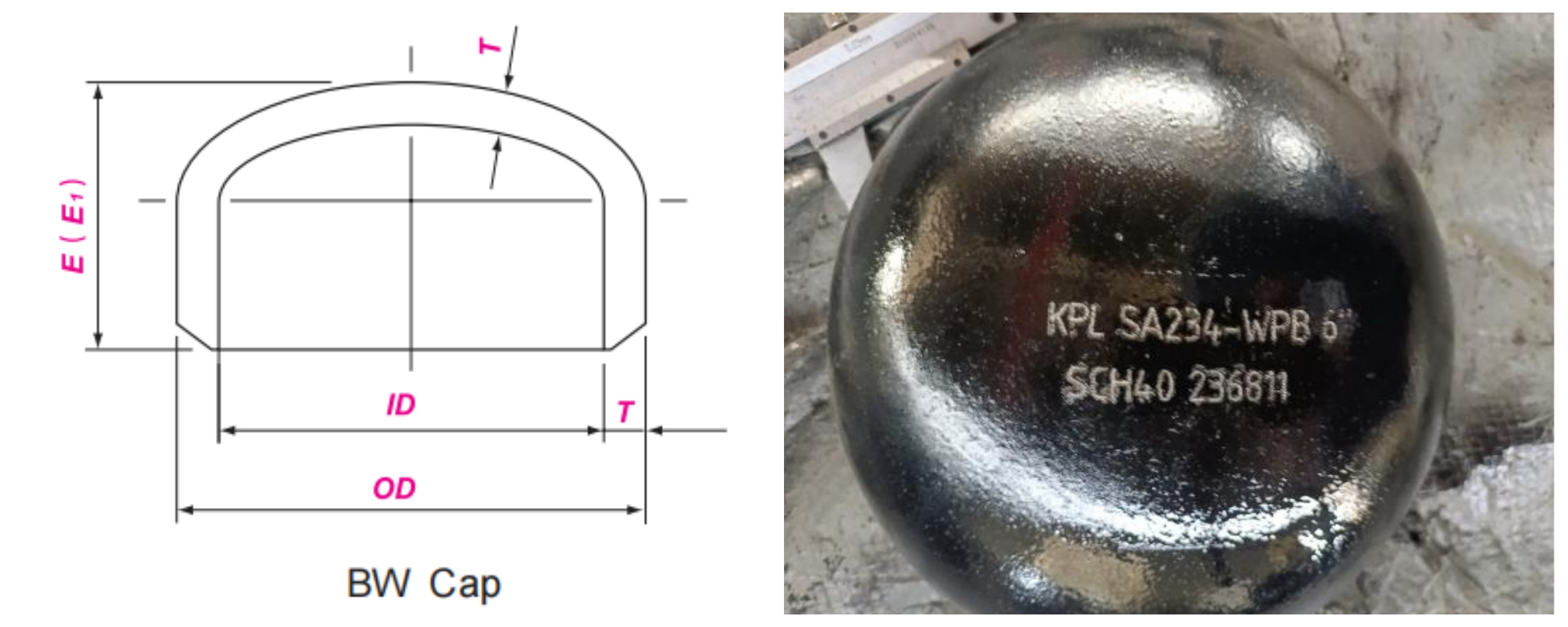

ASTM A234 WPB 管帽是一种配件,可简化系统中压力容器或管道末端的密封。它们也被称为管端,因为管帽用于管道的最末端。管帽通常为半球形或椭圆形的封头结构,其一端封闭,另一端与管道连接。管帽的外径与所连接管道的外径相匹配。

管帽最主要的功能是封闭管道的端部。在管道系统中,无论是输送液体还是气体的管道,管帽都可以防止介质泄漏,同时也能防止外界杂质进入管道内部。在一些特殊的管道布局中,管帽可以与其他管件配合改变流体的流向。对焊管帽广泛应用于石油化工、核电、机械、造船、防水处理、管道等多个领域。

ASTM A234 WPB 管帽的规格

Specification: | ASTM A234 WPB End Cap |

Size: | 1/2” – 48” / DN15 – 1200 |

Type: | Butt Weld (BW), Seamless (SMLS) Welded |

Thickness: | SCH10 SCH20 STD SCH40 SCH60 SCH80 SCHXS SCH100 SCH120 SCH140 SCH160 SCHXXS |

Standard | ASME B16.9 |

Type Of Dimension: | BS1640, EN 10253 - 4, DIN 2605, JIS B2312, ANSI B16.9, MSS SP-75, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2313 |

Carbon Steel | A234WPB/WPC |

ASME B16.9 管帽的尺寸

DN | NPS | OD | E | E1 |

15 | 1/2 | 21.3 | 25 | 25 |

20 | 3/4 | 26.7 | 25 | 25 |

25 | 1 | 33.4 | 38 | 38 |

32 | 11/4 | 42.2 | 38 | 38 |

40 | 11/2 | 48.3 | 38 | 38 |

50 | 2 | 60.3 | 38 | 44 |

65 | 21/2 | 73.0 | 38 | 51 |

80 | 3 | 88.9 | 51 | 64 |

90 | 31/2 | 101.6 | 64 | 76 |

100 | 4 | 114.3 | 64 | 76 |

125 | 5 | 141.3 | 76 | 89 |

150 | 6 | 168.3 | 89 | 102 |

200 | 8 | 219.1 | 102 | 127 |

250 | 10 | 273.0 | 127 | 152 |

300 | 12 | 323.8 | 152 | 178 |

350 | 14 | 355.6 | 165 | 191 |

400 | 16 | 406.4 | 178 | 203 |

450 | 18 | 457.0 | 203 | 229 |

500 | 20 | 508.0 | 229 | 254 |

550 | 22 | 559.0 | 254 | 254 |

600 | 24 | 610.0 | 267 | 305 |

650 | 26 | 660.0 | 267 | --- |

700 | 28 | 711.0 | 267 | --- |

750 | 30 | 762.0 | 267 | --- |

800 | 32 | 813.0 | 267 | --- |

850 | 34 | 864.0 | 267 | --- |

900 | 36 | 914.0 | 267 | --- |

950 | 38 | 965.0 | 305 | --- |

1000 | 40 | 1016.0 | 305 | --- |

1050 | 42 | 1067.0 | 305 | --- |

1100 | 44 | 1118.0 | 343 | --- |

1150 | 46 | 1168.0 | 343 | --- |

1200 | 48 | 1219.0 | 343 | --- |

碳钢对焊管件的公差范围

对焊管件的公差 | |||||||||||||

公称尺寸Nominal Size | 所有管件1)2) |

| 3D 弯头 | 180 " 弯头 | 管帽 | 异径管 、 | 翻边短节 | ||||||

DN | NPS | OD 3) 4) | ID 3) |

|

| O | K | U | E, E1 |

| G | R | t |

15-65 | 1/2 -21/2 | +1.6 | ±0.8 | ±2 |

±3 |

±6 | ±6 | ±1 | ±3 | ±2 | 0 | 0 | +1.6 |

80-90 | 3-31/2 | ±1.6 | ±1.6 | ±2 | ± 3 | ± 6 | ±6 | ±1 | ±3 | ±2 | 0 | 0 | +1.6 |

100 | 4 | ±1.6 | ±1.6 | ±2 |

±3 |

±6 | ±6 | ±1 | ±3 | ±2 | 0 | 0 | +1.6 |

125-200 | 5-8 | +2.4 | ±1.6 | ±2 |

±3 |

±6 | ±6 | ±1 | ±6 | ±2 | 0 | 0 | +1.6 |

250-450 | 10-18 | +4.0 | ±3.2 | ±2 |

±3 | ±10 | ±6 | ±2 | ±6 | ±2 | 0 | 0 | +3.2 |

500-600 | 20-24 | +6.4 | ±4.8 | ±2 |

±3 | ±10 | ±6 | ±2 | ±6 | ±2 | 0 | 0 | +3.2 |

650-750 | 26-30 | +6.4 | ±4.8 | ±3 |

±6 | --- | --- | --- | ±10 | ±5 | --- | --- | --- |

800-1200 | 32-48 | +6.4 | ± 4.8 | ±5 |

±6 | --- | --- | --- | ±10 | ±5 | --- | --- | --- |

1300-1500 | 52-60 | +6.4 | ±4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

1600-1700 | 64-68 | +6.4 | ± 4.8 | ±5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

1800-2000 | 72-80 | +6.4 | ±4.8 | ±5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

对焊管帽的材质等级

碳钢管帽

ASTM A234 WPB/WPC, ASTM A420 WPL6, ASTM A860 WPHY 42 / 46 / 56 / 60 / 65

合金钢管帽

ASTM A234 WP11 / WP12 / WP5 / WP9 / WP22 / WP91 / WP92,

不锈钢管帽

ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L, A815 S32205, S31803, 32750, 32760

A234 WPB 管帽的材质特点

A234 WPB 管帽的化学成分

CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | Cb | V |

ASTM A234 WPB | MIN | 0.29 | 0.10 | |||||||||

MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | / | 0.08 |

A234 WPB 管帽中锰含量在0.29% - 1.06%左右。锰在A234 WPB 材质中具有多种作用。首先,它可以提高钢材的强度,与碳元素协同作用,增强钢材的承载能力。其次,锰能够增加钢材的韧性,使材料在承受外力时不容易发生脆性断裂。

A234 WPB 管帽的机械性能

MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

ASTM A234 WPB | 415 min | 240 min | 22 min | 30 min | 197 max |

A234 WPB 材质具有一定的强度,其屈服强度通常在240MPa左右,抗拉强度在415MPa以上。由于其良好的强度和韧性的结合,A234 WPB 管帽在管道系统中是可靠的部件。在长期使用过程中,它能够抵抗管道内介质的压力波动、温度变化等因素的影响,减少因管帽损坏而导致的管道故障风险。

内容为空!