浏览数量: 156 作者: Chaos 发布时间: 2024-06-05 来源: 本站

不锈钢锻制管件是一种重要的工业管道配件,主要由不锈钢材料制成,这种材料具有优异的耐腐蚀性、耐高温性和机械性能。不锈钢锻制管件的类型丰富多样,主要用于连接、传输流体或气体介质,在石油、化工、电力、制药、食品等多个行业中都有广泛的应用。

不锈钢锻制管件的类型

不锈钢锻制管件需要经过多道工序,包括材料选择、锻造、热处理、机械加工和检验等。这些管件通常具有较高的尺寸精度和表面质量,丰富多样的管件种类,可以满足严格的工程要求和使用环境。

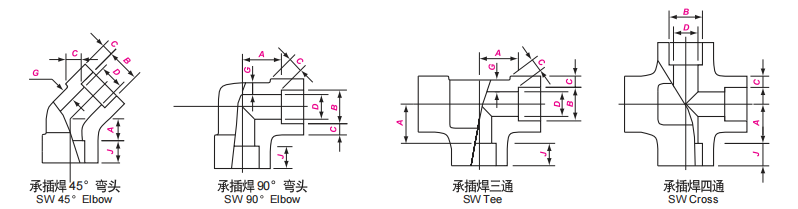

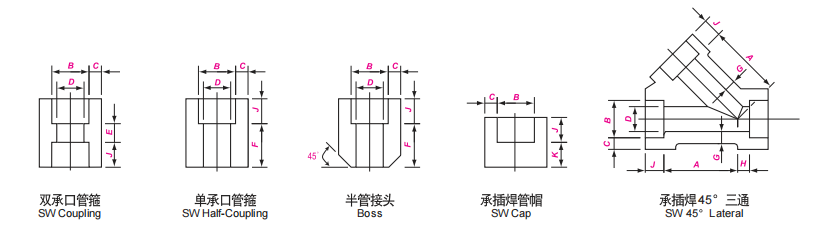

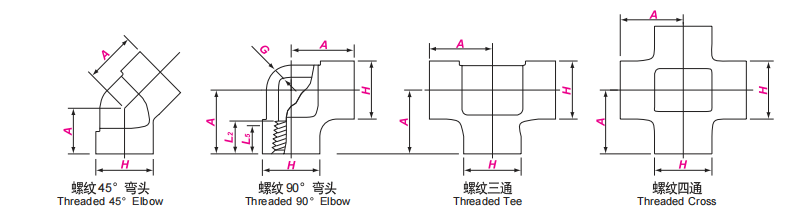

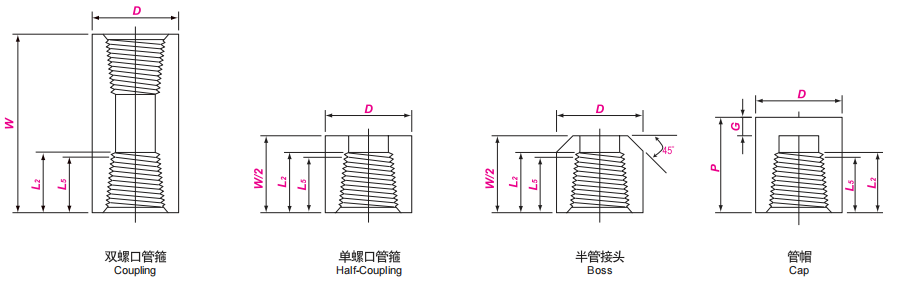

按照连接方式可分为承插管件和螺纹管件

承插管件包括:承插弯头,承插三通,承插四通,承插管箍,承插管帽,承插半管接头,承插45度斜三通,承插活接头;

尺寸范围:1/8英寸-4英寸;

压力范围:CLASS 3000 6000 9000.

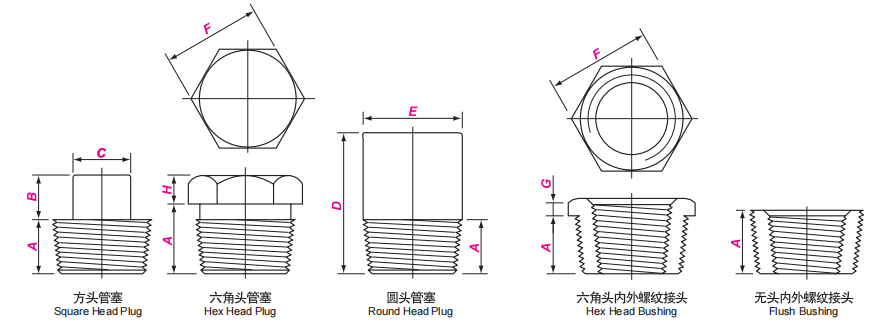

螺纹管件包括:螺纹45度弯头,螺纹90度弯头,螺纹三通,螺纹四通,内外螺纹90度弯头,螺纹管箍,螺纹半管接头,螺纹管帽,螺纹管塞,螺纹补芯,螺纹活接头,螺纹渐缩管等。

尺寸范围:1/8英寸-4英寸;

压力范围:CLASS 2000 3000 6000.

ASME B16.11不锈钢锻制管件类型

不锈钢锻制管件的生产标准包括ASME B16.11;MSS SP-83;MSS SP-97;MSS SP-95等。其中ASME B16.11生产标准应用最为广泛。ASME B16.11标准是美国标准协会发布的一个针对锻制的高压管件的生产标准。具体来说,ASME B16.11标准对高压锻制管件的材料、尺寸、形状、压力等级,公差范围等方面都有详细的要求。

ASME B16.11 承插管件的尺寸

Nominal Size | Socket | Bore Dia.of Fitings | Socket Wall Thickness | Body Wal | Depth of | Center to Bottom of Socket | |||||||||||||||

D N | NPS | B | D | C | Gmin | J mim | A | ||||||||||||||

3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90 Elbow Tee Cross | 45 Elbow | |||||||||||

ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 11.0 | 11.0 | 8 | 8 | ||||||

8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 | 11.0 | 13.5 | 8 | 8 | ||||||

10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 | 13.5 | 15.5 | 8.0 | 11.0 | ||||||

15 | 1/2 | 21.9 | 15.0 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19.0 | 25.5 | 11 | 12.5 | 15.5 |

20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19.0 | 22.5 | 28.5 | 13 | 14 | 19 |

25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 |

32 | 1-1/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 |

40 | 1-1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 |

50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 |

65 | 2-1/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 | 16.0 | 41.0 | 28.5 | ||||||||||||

80 | 3 | 89.9 | 76.4 | 9.52 | 8.30 | 7.62 | 16.0 | 57.0 | 32.0 | ||||||||||||

100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 | 19.0 | 66.5 | 41.0 | ||||||||||||

Note | |||||||||||||||||||||

Nominal Size | Socket | Bore Dia.of Fittings | Socket Wall Thickness | Body Wall | Depth of | Laying | Laying | End Wall Thickness | Center to Bottom of Socket | |||||||||||||||

D N | NPS | B | D | C | n | min | E | F | Kmin | A | H | |||||||||||||

3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 3000 | 6000 | |||||||||

ave | min | ave | min | ave | min | |||||||||||||||||||

6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 |

| ||||||||

8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.3 | 4.6 | 4.01 | 3.02 | 3.68 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 | |||||||||

10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.5 | 5.03 | 4.37 | 3.2 | 4.01 | 9.5 | 6.5 | 17.5 | 4.8 | 6.4 | 37 | 9.5 | |||||||

15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 9.5 | 22.5 | 6.4 | 7.9 | 11.2 | 41 | 51 | 9.5 | 11 |

20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 9.5 | 24 | 6.4 | 7.9 | 12.7 | 51 | 60 | 11 | 13 |

25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 12.5 | 28.5 | 9.6 | 11.2 | 14.2 | 60 | 71 | 13 | 16 |

32 | 1-1/4 | 42.8 | 34.3 | 42.1 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 12.5 | 30 | 9.6 | 11.2 | 14.2 | 71 | 81 | 16 | 17 |

40 | 1-1/2 | 48.9 | 40.1 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 12.5 | 32 | 112 | 12.7 | 15.7 | 81 | 98 | 17 | 21 | |

50 | 2 | 61.2 | 51.7 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 19 | 41 | 12.7 | 15.7 | 19 | 98 | 151 | 21 | 30 | |

65 | 2-1/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 |

| 16 | 19 | 43 | 15.7 | 19 | 151 | 30 | ||||||||||

80 | 3 | 89.9 | 76.4 | 9.52 | 8.3 | 7.62 | 16 | 19 | 44.5 | 19 | 22.4 | 184 | 57 | |||||||||||

100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 |

| 19 | 19 | 48 | 22.4 | 28.4 | 201 | 66 | ||||||||||

Note(con finued): | ||||||||||||||||||||||||

公差范围

TOLERANCES FOR SW FITTINGS | ||||||||||

Nominal Size | Aa Fttings | Ebows, | Couping | Half- | Reducer Inserts | Unions | ||||

Socket | Bore Dia.of | Center to | Laying | Laying | Laying | Shank Dia | Length | Laying | ||

DN | NPS | B | D | A,H | E | F | A | SD | SL | E |

6月8日 | 1/8-1-1/4 | +0.4 | +1.5 | ±1.0 | ±1.5 | ±1.0 | +1.5 | ±0.25 | 0 | ±1.5 |

10月20日 | 3/8-3/4 | +0.4 | +1.5 | ±1.5 | ±3.0 | ±1.5 | +1.5 | ±0.25 | 0 | ±3.0 |

25-40 | 1-1-1/2 | +0.4 | +1.5 | ±2.0 | ±4.0 | ±2.0 | +2.0 | ±0.25 | 0 | ±4.0 |

50 | 2 | +0.5 | +1.5 | ±2.0 | ±4.0 | ±2.0 | +2.0 | ±0.5 | 0 | ±4.0 |

65-80 | 2-1/2-3 | +0.5 | +3.0 | ±2.5 | ±5.0 | ±2.5 | +2.5 | +0.5 | 0 | ±5.0 |

100 | 4 | +0.5 | +3.0 | ±2.5 | ±5.0 | ±±2.5 | +2.5 | ±0.7 | 0 | - |

ASME B16.11螺纹管件尺寸

Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||||||

DN | NPS | A | H | G min | min | mim | |||||||||

90 Ebows Tees Crosses | 45 Elbows | ||||||||||||||

2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | ||||

6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

32 | 1-1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 84 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

65 | 2-1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

Note: 1)Thread shall be machined per GB/T 12716(equivalent to ASME B1.20.1) | |||||||||||||||

Nominal Size | End-to-End | End-to-End | Outside Diameter | End Wall | Length of Thread | |||||

DN | NPS | W | P | D | G min | L5 min | L2 min | |||

3000&6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

6 | 1/8 | 32 | 19 | 27 | 16 | 22 | 4.8 | / 6.4 | 6.4 | 6.7 |

15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

32 | 1-1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

65 | 2-1/2 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

Note: 1)Thread shall be machined per GB/T 12716(equivalent to ASME B1.20.1) | ||||||||||

Nominal Size | Leng | Square Height | Width Flats | Head Diameter | Length | Hex Height | Hex Height | Hex Width Flats | |

DN | NPS | A min | B min | C min | E nom | D mim | H min | G min | F nom |

6 | 1/8 | 10 | 6 | 7 | 10 | 35 | 6 | / 3 | 11 |

15 | 1/2 1 | 14 | 10 | 14 | 21 | 44 | 8 | 5 | 22 |

32 | 1-1/4 | 21 | 14 | 24 | 43 | 51 | 14 | 7 | 46 |

65 | 2-1/2 | 27 | 19 | 36 | 73 | 70 | 19 | 10 | 75 |

Note: 1)Threadshall be machined per GB/T 12716(equivalent to ASME B1.20.1). | |||||||||

公差范围

TOLERANCES FOR THRD FITTINGS | ||||

Nominal Size | Ebows Tees Crosses | Couplings | Half couplings | |

Center-to-End | End-to-End | End-to-End | ||

D N | NPS | A、J | W | W/2 |

6-8 | 1/8-1/4 | ±1.0 | ±1.0 | ±1.0 |

10-20 | 3/8-3/4 | ±1.5 | ±1.5 | ±1.5 |

25-50 | 1-2 | ±2.0 | ±2.0 | ±2.0 |

65-100 | 2-1/2-4 | ±2.5 | ±2.5 | ±2.5 |

不锈钢锻制管件压力对应表

CLASS OF THE FITTINGS VS THE GRADE OF THE CONNNECTING PIPES | |||||

Joint Type | Class | Grade of Conneding Pipes | Joint Type | Class | Grade of Connecting Pipes |

SW | 3000 | Sch80、XS | THRD | 2000 | Sch80、XS |

6000 | Sch160 | 3000 | Sch160 | ||

9000 | XXS | 6000 | XXS | ||

Note; | |||||

不锈钢锻制管件的材料类型

不锈钢锻制管件是一种高质量、高性能的管道连接件,广泛应用于石油、天然气、化工和电力等行业中需要承受高温和高压的管道系统。不锈钢锻制管件对应的美标材料标准对应的是ASTM A182,常见的材料类型有不锈钢F304/316;双相不锈钢F51/F53等。

化学成分

CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

机械性能

MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F51 | ASTM A182 F53 |

T.S (MPA) | 515 min | 515 min | 620 min | 800 min |

Y.S (MPA) | 205 min | 205 min | 450 min | 550 min |

EL % | 30 min | 30 min | 35 min | 25 min |

R/A % | 50 min | 50 min | 45 min | 15 min |

HARDNESS | 310 max |

不锈钢锻制管件作为一种高品质、高性能的管件,具有广泛的应用前景。在选择和使用锻制管件时,应关注其品质和性能,确保流体输送的安全、稳定和高效,为各行业的流体输送系统提供可靠的保障。

内容为空!