浏览数量: 49 作者: 本站编辑 发布时间: 2026-02-02 来源: 本站

ASME B16.20法兰垫片标准是美国机械工程师学会(ASME)发布的规范管道法兰用金属缠绕垫片、覆盖垫片及金属环垫片的设计、制造与尺寸的权威指南。遵循此标准选用的垫片,是确保法兰接口在高温、高压及苛刻介质环境下实现紧密密封的基础保障。

在石油化工、电力、能源等工业领域,管道系统的密封可靠性直接关系到生产安全与运行效率。法兰作为管道系统中重要的连接配件,其密封性能取决于另一个重要配件--法兰垫片。

ASME B16.20标准全称为《管道法兰用金属缠绕垫片、覆盖垫片及金属环垫片》。它与ASME B16.5(管法兰和法兰管件)、ASME B16.47(大直径钢制法兰)等法兰标准配套使用,共同构成了完整的法兰连接规范体系。

该标准详细规定了:

垫片类型:明确了各类垫片的结构形式。

尺寸与公差:对垫片的内外径、厚度等关键尺寸及其允许偏差做出了精确要求,确保与法兰密封面完美匹配。

材料组合:指导填充材料、金属带、覆盖层及金属环的材料选择。

标记与验收:规定了产品的标识方式和检验基准。

选用符合ASME B16.20标准的垫片,意味着其尺寸、性能与相应的ASME标准法兰具有兼容性和互换性,是实现“标准密封”的关键。

根据ASME B16.20,法兰垫片主要分为以下几大类,各自对应不同的法兰密封面型式和工况:

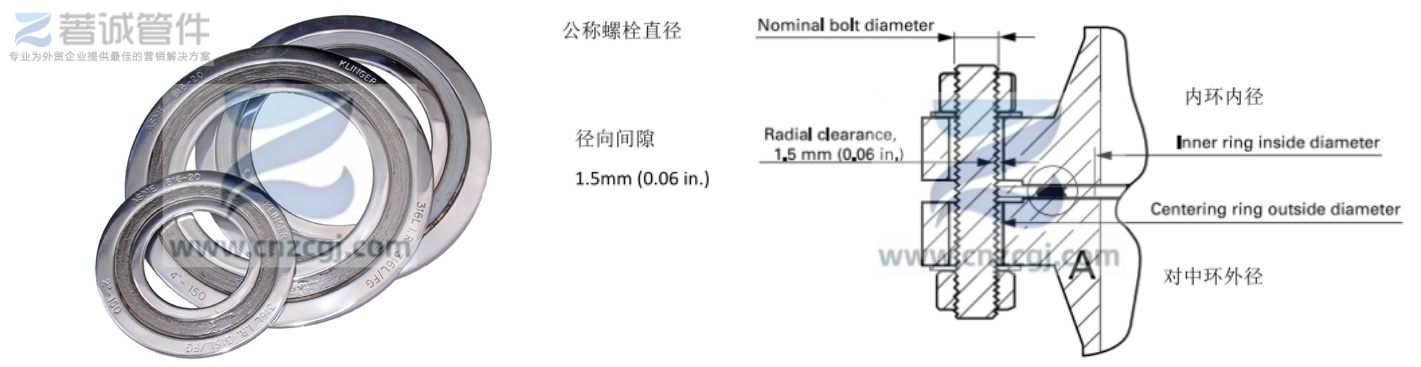

结构:由预成型金属带与非金属填充材料(如石墨、聚四氟乙烯PTFE、陶瓷纤维等)交替螺旋缠绕而成,通常内外带有金属加强环。

适用法兰:主要用于突面(RF)、凹面/凸面(FM/M)及榫面/槽面(T/G)法兰。

特点与应用:兼具金属的强度与非金属的弹性,补偿能力好,适用于广泛的温度压力范围,是石油化工、电力行业应用最广泛的垫片类型之一。

| 法兰尺寸(NPS) | 垫片外径 | 垫片内径 | 中环外径 | |||||||||||||

| Class 150 300 400 600 | Class 900 1500 2500 | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 | |

| 1/2 | 31.8 | 31.8 | 19.1 | 19.1 | 使用Class600 | 19.1 | 使用Class1500 | 19.1 | 19.1 | 47.8 | 54.1 | 使用Class600 | 54.1 | 使用Class1500 | 63.5 | 69.9 |

| 3/4 | 39.6 | 39.6 | 25.4 | 25.4 | 使用Class600 | 25.4 | 使用Class1500 | 25.4 | 25.4 | 57.2 | 66.8 | 使用Class600 | 66.8 | 使用Class1500 | 69.9 | 76.2 |

| 1 | 47.B | 47.8 | 31.8 | 31.8 | 使用Class600 | 31.8 | 使用Class1500 | 31.8 | 31.8 | 66.8 | 73.2 | 使用Class600 | 73.2 | 使用Class1500 | 79.5 | 85.9 |

| 1-1/4 | 60.5 | 60.5 | 47.8 | 47.8 | 使用Class600 | 47.8 | 使用Class1500 | 39.6 | 39.6 | 76.2 | 82.6 | 使用Class600 | 82.6 | 使用Class1500 | 88.9 | 104.9 |

| 1-1/2 | 69.9 | 69.9 | 54.1 | 54.1 | 使用Class600 | 54.1 | 使用Class1500 | 47.8 | 47.8 | 85.9 | 95.3 | 使用Class600 | 95.3 | 使用Class1500 | 98.6 | 117.6 |

| 2 | 85.9 | 85.9 | 69.9 | 69.9 | 使用Class600 | 69.9 | 使用Class1500 | 58.7 | 58.7 | 104.9 | 111.3 | 使用Class600 | 111.3 | 使用Class1500 | 143.0 | 146.1 |

| 2-1/2 | 98.6 | 98.6 | 82.6 | 82.6 | 使用Class600 | 82.6 | 使用Class1500 | 69.9 | 69.9 | 124.0 | 130.3 | 使用Class600 | 130.3 | 使用Class1500 | 165.1 | 168.4 |

| 3 | 120.7 | 120.7 | 101.6 | 101.6 | 使用Class600 | 1016 | 95.3 | 92.2 | 92.2 | 136.7 | 149.4 | 使用Class600 | 149.4 | 168.4 | 174.8 | 196.9 |

| 3-1/2 | 133.4 | - | 114.3 | 114.3 | 使用Class600 | 104.8 | 使用Class1500 | - | - | 161.9 | 165.1 | 使用Class600 | 161.9 | 使用Class1500 | - | - |

| 4 | 149.4 | 149.4 | 127.0 | 1270 | 120.7 | 120.7 | 120.7 | 117.6 | 117.6 | 174.8 | 181.1 | 177.8 | 193.8 | 206.5 | 209.6 | 235.0 |

| 5 | 177.8 | 177.8 | 155.7 | 155.7 | 147.6 | 147.6 | 147.6 | 143.0 | 143.0 | 196.9 | 215.9 | 212.9 | 241.3 | 247.7 | 254.0 | 279.4 |

| 6 | 209.6 | 209.6 | 182.6 | 182.6 | 174.8 | 174.8 | 174.8 | 171.5 | 171.5 | 222.3 | 251.0 | 247.7 | 266.7 | 289.1 | 282.7 | 317.5 |

| 8 | 263.7 | 257.3 | 233.4 | 233.4 | 225.6 | 225.6 | 222.3 | 215.9 | 215.9 | 279.4 | 308.1 | 304.8 | 320.8 | 358.9 | 352.6 | 387.4 |

| 10 | 3175 | 311.2 | 287.3 | 287.3 | 274.6 | 274.6 | 276.4 | 266.7 | 270.0 | 339.9 | 362.0 | 358.9 | 400.1 | 435.1 | 435.1 | 476.3 |

| 12 | 374.7 | 368.3 | 339.9 | 339.9 | 3272 | 327.2 | 323.9 | 323.9 | 317.5 | 409.7 | 422.4 | 419.1 | 457.2 | 498.6 | 520.7 | 549.4 |

| 14 | 406.4 | 400.1 | 371.6 | 371.6 | 362.0 | 362.0 | 355.6 | 362.0 | - | 450.9 | 485.9 | 482.6 | 492.3 | 520.7 | 577.9 | - |

| 16 | 463.6 | 457.2 | 422.4 | 422.4 | 412.8 | 412.8 | 412.8 | 406.4 | - | 514.4 | 539.8 | 536.7 | 565.2 | 574.8 | 641.4 | - |

| 18 | 527.1 | 520.7 | 474.7 | 474.7 | 469.9 | 469.9 | 463.6 | 463.6 | - | 549.4 | 596.9 | 593.9 | 612.9 | 638.3 | 704.9 | - |

| 20 | 577.9 | 571.5 | 525.5 | 525.5 | 520.7 | 520.7 | 520.7 | 514.4 | - | 606.6 | 654.1 | 647.7 | 682.8 | 698.5 | 755.7 | - |

| 24 | 685.8 | 679.5 | 628.7 | 628.7 | 628.7 | 628.7 | 628.7 | 616.0 | - | 7,176 | 774.7 | 768.4 | 790.7 | 838.2 | 901.7 | - |

| 法兰尺寸(NPS) | Class150 | Class300 | Class400 | Class600 | Class900 | ||||||||||

| 垫片 | 对中环外径 | 垫片 | 对中环外径 | 垫片 | 对中环外径 | 垫片 | 对中环外径 | 垫片 | 对中环外径 | ||||||

| 内径 | 外径 | 内径 | 外径 | 内径 | 外径 | 内径 | 外径 | 内径 | 外径 | ||||||

| 26 | 673.1 | 704.9 | 774.7 | 685.8 | 736.6 | 835.2 | 685.8 | 736.6 | 831.9 | 685.8 | 736.6 | 866.9 | 685.8 | 736.6 | 882.7 |

| 28 | 723.9 | 755.7 | 831.9 | 736.6 | 787.4 | 898.7 | 736.6 | 787.4 | 892.3 | 736.6 | 787.4 | 914.4 | 736.6 | 7874 | 946.2 |

| 30 | 774.7 | 806.5 | 882.7 | 793.8 | 844.6 | 952.5 | 793.8 | 844.6 | 946.2 | 793.8 | 844.6 | 971.6 | 793.8 | 844.6 | 1009.7 |

| 32 | 825.5 | 860.6 | 939.8 | 850.9 | 901.7 | 1006.6 | 850.9 | 901.7 | 1003.3 | 850.9 | 901.7 | 1022.4 | 850.9 | 901.7 | 1073.2 |

| 34 | 876.3 | 911.4 | 990.6 | 901.7 | 952.5 | 1057.4 | 901.7 | 952.5 | 1054.1 | 901.7 | 952.5 | 1073.2 | 901.7 | 952.5 | 1136.7 |

| 36 | 927.1 | 968.5 | 1047.8 | 955.8 | 1006.6 | 1117.6 | 955.8 | 1006.6 | 1117.6 | 955.8 | 1006.6 | 1130.3 | 958.9 | 1009.7 | 1200.2 |

| 38 | 977.9 | 1019.3 | 1111.3 | 977.9 | 1016 | 1054.1 | 971.6 | 1022.4 | 1073.2 | 990.6 | 1041.4 | 1104.9 | 1035.1 | 1085.9 | 1200.2 |

| 40 | 1028.7 | 1070.1 | 1162.1 | 1022.4 | 1070.1 | 1114.6 | 1025.7 | 1076.5 | 1127.3 | 1047.8 | 1098.6 | 1155.7 | 1098.6 | 1149.4 | 1251 |

| 42 | 1079.5 | 1124 | 1219.2 | 1073.2 | 1120.9 | 1165.4 | 1076.5 | 1127.3 | 1178.1 | 1104.9 | 1155.7 | 1219.2 | 1149.4 | 1200.2 | 1301.8 |

| 44 | 1130.3 | 1178.1 | 1276.4 | 1130.3 | 11811 | 1219.2 | 1130.3 | 1181.1 | 1231.9 | 1162.1 | 1212.9 | 1270 | 1206.5 | 1257.3 | 1368.6 |

| 46 | 1181.1 | 1228.9 | 1327.2 | 1178.1 | 1228.9 | 1273.3 | 1193.8 | 1244.6 | 1289.1 | 1212.9 | 1263.7 | 1327.2 | 1270 | 1320.8 | 1435.1 |

| 48 | 1231.9 | 1279.7 | 1384.3 | 1235.2 | 1286 | 1324.1 | 1244.6 | 1295.4 | 1346.2 | 1270 | 1320.8 | 1390.7 | 1320.8 | 1371.6 | 1485.9 |

| 50 | 1282.7 | 1333.5 | 1435.1 | 1295.4 | 1346.2 | 1378 | 1295.4 | 1346.2 | 1403.4 | 1320.8 | 1371.6 | 1447.8 | - | - | - |

| 52 | 1333.5 | 1384.3 | 1492.3 | 1346.2 | 1397 | 1428.8 | 1346.2 | 1397 | 1454.2 | 1371.6 | 1422.4 | 1498.6 | - | - | - |

| 54 | 1384.3 | 1435.1 | 1549.4 | 1403.4 | 1454.2 | 1492.3 | 1403.4 | 1454.2 | 1517.7 | 1428.8 | 1479.6 | 1555.8 | - | - | - |

| 56 | 1435.1 | 1485.9 | 1606.6 | 1454.2 | 1505 | 1543.1 | 1454.2 | 1505 | 1568.5 | 1479.6 | 1530.4 | 1612.9 | - | - | - |

| 58 | 1485.9 | 1536.7 | 1663.7 | 1511.3 | 1562.1 | 1593.9 | 1505 | 1555.8 | 1619.3 | 1536.7 | 1587.5 | 1663.7 | - | - | - |

| 60 | 1536.7 | 1587.5 | 1714.5 | 1562.1 | 1612.9 | 1644.7 | 1568.5 | 1619.3 | 1682.8 | 1593.9 | 1644.7 | 1733.6 | - | - | - |

| 法兰尺寸(NPS) | Class150 | Class300 | Class400 | Class600 | Class900 | ||||||||||

| 垫片 | 对中环外径 | 垫片 | 对中环外径 | 垫片 | 对中环外径 | 垫片 | 对中环外径 | 垫片 | 对中环外径 | ||||||

| 内径 | 外径 | 内径 | 外径 | 内径 | 外径 | 内径 | 外径 | 内径 | 外径 | ||||||

| 26 | 673.1 | 698.5 | 725.4 | 673.1 | 711.2 | 771.7 | 666.8 | 698.5 | 746.3 | 663.7 | 714.5 | 765.3 | 692.2 | 749.3 | 838.2 |

| 28 | 723.9 | 749.3 | 776.2 | 723.9 | 762 | 825.5 | 714.5 | 749.3 | 800.1 | 704.9 | 755.7 | 8192 | 743 | 800.1 | 901.7 |

| 30 | 774.7 | 800.1 | 827 | 774.7 | 812.8 | 886 | 765.3 | 806.5 | 857.3 | 778 | 828.8 | 879.6 | 8065 | 8573 | 958.9 |

| 32 | 825.5 | 850.9 | 881.1 | 825.5 | 863.6 | 939.8 | 812.8 | 860.6 | 911.4 | 831.9 | 882.7 | 933.5 | 863.6 | 914.4 | 1016 |

| 34 | 876.3 | 908.1 | 935 | 876.3 | 914.4 | 993.9 | 866.9 | 911.4 | 962.2 | 8B9.0 | 939.8 | 997 | 920.8 | 971.6 | 1073.2 |

| 36 | 927.1 | 958.9 | 987.6 | 927.1 | 965.2 | 1047.8 | 917.7 | 965.2 | 1022.4 | 939.8 | 990.6 | 1047.8 | 946.2 | 997 | 1124 |

| 38 | 974.9 | 1009.7 | 1044.7 | 1009.7 | 1047.8 | 1098.6 | 971.6 | 1022.4 | 1073.2 | 990.6 | 1041.4 | 1104.9 | 1035.1 | 1085.9 | 1200.2 |

| 40 | 1022.4 | 10638 | 1095.5 | 1060.5 | 1098.6 | 11494 | 1025.7 | 1076.5 | 1127.3 | 1047.8 | 1098.6 | 1155.7 | 1098.6 | 1149.4 | 1251 |

| 42 | 1079.5 | 1114.6 | 1146.3 | 1111.3 | 1149.4 | 1200.2 | 1076.5 | 1127.3 | 1178.1 | 1104.9 | 1155.7 | 1219.2 | 1149.4 | 1200.2 | 1301.8 |

| 44 | 1124 | 1165.4 | 1197.1 | 1162.1 | 1200.2 | 1251 | 1130.3 | 1181.1 | 1231.9 | 1162.1 | 1212.9 | 1270 | 1206.5 | 1257.3 | 1368.6 |

| 46 | 1181.1 | 1224 | 1255.8 | 1216.2 | 1254.3 | 1317.8 | 1193.8 | 1244.6 | 1289.1 | 1212.9 | 1263.7 | 1327.2 | 1270 | 1320.8 | 1435.1 |

| 48 | 1231.9 | 1270 | 1306.6 | 1263.7 | 1311.4 | 1368.6 | 1244.6 | 1295.4 | 1346.2 | 1270 | 1320.8 | 1390.7 | 1320.8 | 1371.6 | 1485.9 |

| 50 | 1282.7 | 1325.6 | 1357.4 | 1317.8 | 1355.9 | 1419.4 | 1295.4 | 1346.2 | 1403.4 | 1320.8 | 1371.6 | 1447.8 | - | - | - |

| 52 | 1333.5 | 1376.4 | 1408.2 | 1368.6 | 1406.7 | 1470.2 | 1346.2 | 1397 | 1454.2 | 1371.6 | 1422.4 | 1498.6 | - | - | - |

| 54 | 1384.3 | 1422.4 | 1463.8 | 1403.4 | 1454.2 | 15304 | 1403.4 | 1454.2 | 1517.7 | 1428.8 | 1479.6 | 1555.8 | - | - | - |

| 56 | 1444.8 | 1478 | 1514.6 | 1479.6 | 1524 | 1593.9 | 1454.2 | 1505 | 1568.5 | 1479.6 | 1530.4 | 1612.9 | - | - | - |

| 58 | 1500.1 | 1528.8 | 1579.6 | 1535.2 | 1573.3 | 1655.8 | 1505 | 1555.8 | 1619.3 | 1536.7 | 1587.5 | 1663.7 | - | - | - |

| 60 | 1557.3 | 1586 | 1630.4 | 15890 | 1630.4 | 1706.6 | 1568.5 | 1619.3 | 1682.8 | 1593.9 | 1644.7 | 1733.6 | - | - | - |

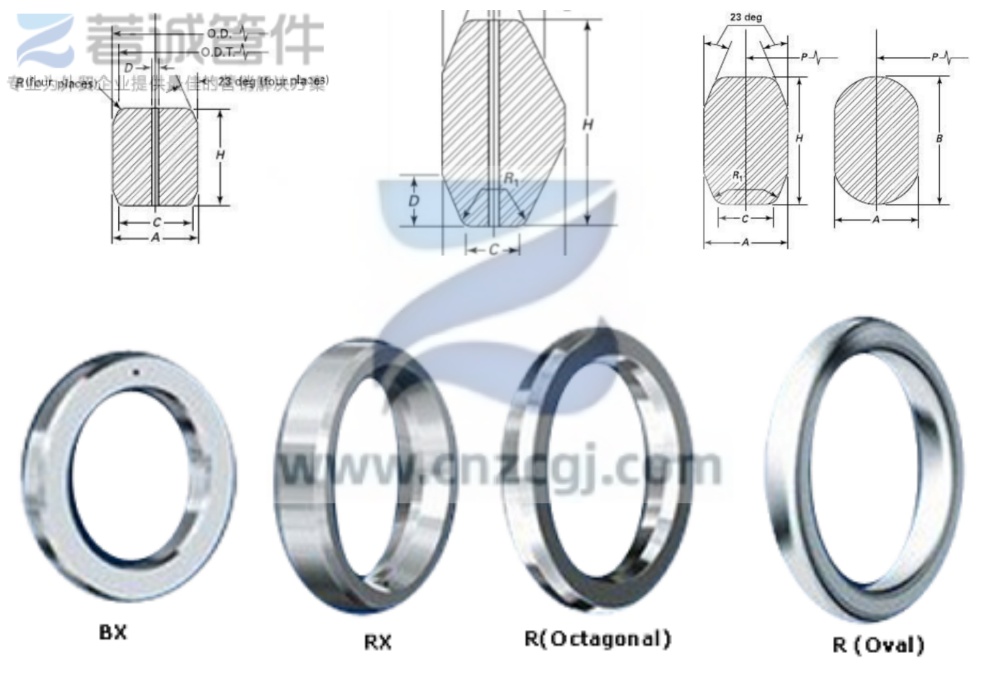

结构:由实心金属加工成特定截面形状(如椭圆形、八角形)的环。

适用法兰:专门用于环连接面(RTJ)法兰。

特点与应用:全金属密封,依靠线接触或面接触产生极高的密封比压。适用于高温、高压及临氢、热循环等极端苛刻工况,常见于采油树、高压换热器及高温蒸汽管道。

| 编号 | 中心圆直径 P mm (in.) | 宽度 A mm (in.) | 高度 mm (in.) | 八角垫片平面宽度 C mm (in.) | 八角垫片半径 Ri mm (in.) | |

| 椭圆形 B | 八角形 H | |||||

| R-11 | 34.14 (1.344) | 6.35 (0.250) | 11.2 (0.44) | 9.7 (0.38) | 4.32 (0.170) | 1.5 (0.06) |

| R-12 | 39.70 (1.563) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-13 | 42.88 (1.688) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-14 | 44.45 (1.750) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-15 | 47.63 (1.875) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-16 | 50.80 (2.000) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-17 | 57.15 (2.250) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-18 | 60.33 (2.375) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-19 | 65.10 (2.563) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-20 | 68.28 (2.688) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-21 | 72.24 (2.844) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-22 | 82.55 (3.250) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-23 | 82.55 (3.250) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-24 | 95.25 (3.750) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-25 | 101.60 (4.000) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-26 | 101.60 (4.000) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-27 | 107.95 (4.250) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-28 | 111.13 (4.375) | 12.70 (0.500) | 19.1 (0.75) | 17.5 (0.69) | 8.66 (0.341) | 1.5 (0.06) |

| R-29 | 114.30 (4.500) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-30 | 117.48 (4.625) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-31 | 123.83 (4.875) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-32 | 127.00 (5.000) | 12.70 (0.500) | 19.1 (0.75) | 17.5 (0.69) | 8.66 (0.341) | 1.5 (0.06) |

| R-33 | 131.78 (5.188) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-34 | 131.78 (5.188) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-35 | 136.53 (5.375) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-36 | 149.23 (5.875) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-37 | 149.23 (5.875) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-38 | 157.18 (6.188) | 15.88 (0.625) | 22.4 (0.88) | 20.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-39 | 161.93 (6.375) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| 编号 | 中心圆直径 P mm (in.) | 宽度 A mm (in.) | 高度 mm (in.) | 八角垫片平面宽度 C mm (in.) | 八角垫片半径 Ri mm (in.) | |

| 椭圆形 B | 八角形 H | |||||

| R-40 | 171.45 (6.750) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-41 | 180.98 (7.125) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-42 | 190.50 (7.500) | 19.05 (0.750) | 25.4 (1.00) | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-43 | 193.68 (7.625) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-44 | 193.68 (7.625) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-45 | 211.15 (8.313) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-46 | 211.15 (8.313) | 12.70 (0.500) | 19.1 (0.75) | 17.5 (0.69) | 8.66 (0.341) | 1.5 (0.06) |

| R-47 | 228.60 (9.000) | 19.05 (0.750) | 25.4 (1.00) | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-48 | 247.65 (9.750) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-49 | 269.88 (10.625) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-50 | 269.88 (10.625) | 15.88 (0.625) | 22.4 (0.88) | 2.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-51 | 279.40 (11.000) | 22.23 (0.875) | 28.7 (1.13) | 26.9 (1.06) | 14.81 (0.583) | 1.5 (0.06) |

| R-52 | 304.80 (12.000) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-53 | 323.85 (12.750) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-54 | 323.85 (12.750) | 15.88 (0.625) | 22.4 (0.88) | 20.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-55 | 342.90 (13.500) | 28.58 (1.125) | 36.6 (1.44) | 35.1 (1.38) | 19.81 (0.780) | 2.3 (0.09) |

| R-56 | 381.00 (15.000) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-57 | 381.00 (15.000) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-58 | 381.00 (15.000) | 22.23 (0.875) | 28.7 (1.13) | 26.9 (1.06) | 14.81 (0.583) | 1.5 (0.06) |

| R-59 | 396.88 (15.625) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-60 | 406.40 (16.000) | 31.75 (1.250) | 39.6 (1.56) | 38.1 (1.50) | 22.33 (0.879) | 2.3 (0.09) |

| R-61 | 406.40 (16.000) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-62 | 419.10 (16.500) | 15.88 (0.625) | 22.4 (0.88) | 20.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-63 | 419.10 (16.500) | 25.40 (1.000) | 33.3 (1.31) | 31.8 (1.25) | 17.30 (0.681) | 2.3 (0.09) |

| R-64 | 454.03 (17.875) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-65 | 469.90 (18.500) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-66 | 469.90 (18.500) | 15.88 (0.625) | 22.4 (0.88) | 20.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-67 | 469.90 (18.500) | 28.58 (1.125) | 36.6 (1.44) | 35.1 (1.38) | 19.81 (0.780) | 2.3 (0.09) |

| R-68 | 517.53 (20.375) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-69 | 533.40 (21.000) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-70 | 533.40 (21.000) | 19.05 (0.750) | 25.4 (1.00) | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-71 | 533.40 (21.000) | 28.58 (1.125) | 36.6 (1.44) | 35.1 (1.38) | 19.81 (0.780) | 2.3 (0.09) |

| R-72 | 558.80 (22.000) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-73 | 584.20 (23.000) | 12.70 (0.500) | 19.1 (0.75) | 17.5 (0.69) | 8.66 (0.341) | 1.5 (0.06) |

| R-74 | 584.20 (23.000) | 19.05 (0.750) | 254 (1.00) | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-75 | 584.20 (23.000) | 31.75 (1.250) | 39.6 (1.56) | 38.1 (1.50) | 22.33 (0.879) | 2.3 (0.09) |

| R-76 | 673.10 (26.500) | 7.95 (0.313) | 14.2 (0.56) | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| R-77 | 692.15 (27.250) | 15.88 (0.625) | 22.4 (0.88) | 20.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-78 | 692.15 (27.250) | 25.40 (1.000) | 33.3 (1.31) | 31.8 (1.25) | 17.30 (0.681) | 2.3 (0.09) |

| R-79 | 692.15 (27.250) | 34.93 (1.375) | 44.5 (1.75) | 41.4 (1.63) | 24.82 (0.977) | 2.3 (0.09) |

| R-80 | 615.95 (24.250) | 7.95 (0.313) | - | 12.7 (0.50) | 5.23 (0.206) | 1.5 (0.06) |

| 编号 | 中心圆直径 P mm (in.) | 宽度 A mm (in.) | 高度 mm (in.) | 八角垫片平面宽度 C mm (in.) | 八角垫片半径 Ri mm (in.) | |

| 椭圆形 B | 八角形 H | |||||

| R-81 | 635.00 (25.000) | 14.30 (0.563) | … | 19.1 (0.75) | 9.58 (0.377) | 1.5 (0.06) |

| R-82 | 57.15 (2.250) | 11.13 (0.438) | … | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-84 | 63.50 (2.500) | 11.13 (0.438) | … | 16.0(0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-85 | 79.38 (3.125) | 12.70 (0.500) | … | 17.5 (0.69) | 8.66 (0.341) | 1.5 (0.06) |

| R-86 | 90.50 (3.563) | 15.88 (0.625) | … | 20.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-87 | 100.03 (3.938) | 15.88 (0.625) | … | 20.6 (0.81) | 10.49 (0.413) | 1.5 (0.06) |

| R-88 | 123.83 (4.875) | 19.05 (0.750) | … | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-89 | 114.30 (4.500) | 19.05 (0.750) | … | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-90 | 155.58 (6.125) | 22.23 (0.875) | … | 26.9 (1.06) | 14.81 (0.583) | 1.5 (0.06) |

| R-91 | 260.35 (10.250) | 31.75 (1.250) | … | 38.1 (1.50) | 22.33 (0.879) | 2.3 (0.09) |

| R-92 | 228.60 (9.000) | 11.13 (0.438) | 17.5 (0.69) | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-93 | 749.30 (29.500) | 19.05 (0.750) | … | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-94 | 800.10 (31.500) | 19.05 (0.750) | … | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-95 | 857.25 (33.750) | 19.05 (0.750) | … | 23.9 (0.94) | 12.32 (0.485) | 1.5 (0.06) |

| R-96 | 914.40 (36.000) | 22.23 (0.875) | … | 26.9 (1.06) | 14.81 (0.583) | 1.5 (0.06) |

| R-97 | 965.20 (38.000) | 22.23 (0.875) | … | 26.9 (1.06) | 14.81 (0.583) | 1.5 (0.06) |

| R-98 | 1022.35 (40.250) | 22.23 (0.875) | … | 26.9 (1.06) | 14.81 (0.583) | 1.5 (0.06) |

| R-99 | 234.95 (9.250) | 11.13 (0.438) | … | 16.0 (0.63) | 7.75 (0.305) | 1.5 (0.06) |

| R-100 | 749.30 (29.500) | 28.58 (1.125) | … | 35.1 (1.38) | 19.81 (0.780) | 2.3 (0.09) |

| R-101 | 800.10 (31.500) | 31.75 (1.250) | … | 38.1 (1.50) | 22.33 (0.879) | 2.3 (0.09) |

| R-102 | 857.25 (33.750) | 31.75 (1.250) | … | 38.1 (1.50) | 22.33 (0.879) | 2.3 (0.09) |

| R-103 | 914.40 (36.000) | 31.75 (1.250) | … | 38.1 (1.50) | 22.33 (0.879) | 2.3 (0.09) |

| R-104 | 965.20 (38.000) | 34.93 (1.375) | … | 41.4 (1.63) | 24.82 (0.977) | 2.3 (0.09) |

| R-105 | 1022.35 (40.250) | 34.93 (1.375) | … | 41.4 (1.63) | 24.82 (0.977) | 2.3 (0.09) |

23度= 角,±0~30′(±1/2度);A = 环垫宽度,±0.20 mm(±0.008 in.);

B,H = 环垫高度,+1.3 mm,-0.5 mm(+0.05 in.,-0.02 in.),在此公差范围内的任何环垫,整个圆周上的高度变化不得超过0.5mm(0.02 in.);

C= 八角形环垫平面宽度,±0.20 mm(±0.008 in.);P= 环垫中心圆直径,±0.18 mm(±0.007 in.);R1= 环垫半径,±0.5mm(±0.02 in.)。

| 编号 | 环垫外径O.D mm (in.) | 环垫宽度 A mm (in.) | 平面宽度 C mm (in.) | 外斜面高度 D mm (in.) | 环垫高度 H mm (in.) | 八角形环垫半径 Ri mm (in.) | 通孔规格 E mm (in.) |

| RX-20 | 76.20 (3.000) | 8.74 (0.344) | 4.62 (0.182) | 3.18 (0.125) | 19.05 (0.750) | 1.5 (0.06) | - |

| RX-23 | 93.27 (3.672) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1000) | 1.5 (0.06) | - |

| RX-24 | 105.97 (4.172) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-25 | 109.55 (4.313) | 8.74 (0.344) | 4.62 (0.182) | 3.18 (0.125) | 19.05 (0.750) | 1.5 (0.06) | - |

| RX-26 | 111.91 (4.406) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-27 | 118.26 (4.656) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-31 | 134.54 (5.297) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-35 | 147.24 (5.797) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-37 | 159.94 (6.297) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-39 | 172.64 (6.797) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-41 | 191.69 (7.547) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-44 | 204.39 (8.047) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-45 | 221.84 (8.734) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-46 | 222.25 (8.750) | 13.49 (0.531) | 6.68 (0.263) | 4.78 (0.188) | 28.58 (1.125) | 1.5 (0.06) | - |

| RX-47 | 245.26 (9.656) | 19.84 (0.781) | 10.34 (0.407) | 6.88 (0.271) | 41.28 (1.625) | 2.3 (0.09) | - |

| RX-49 | 280.59 (11.047) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1000) | 1.5 (0.06) | - |

| RX-50 | 283.36 (11.156) | 16.66 (0.656) | 8.51 (0.335) | 5.28 (0.208) | 31.75 (1.250) | 1.5 (0.06) | - |

| RX-53 | 334.57 (13.172) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-54 | 337.34 (13.281) | 16.66 (0.656) | 8.51 (0.335) | 5.28 (0.208) | 31.75 (1.250) | 1.5 (0.06) | - |

| RX-57 | 391.72 (15.422) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-63 | 441.73 (17.391) | 27.00 (1.063) | 14.78 (0.582) | 8.46 (0.333) | 50.80 (2.000) | 2.3 (0.09) | - |

| RX-65 | 480.62 (18.922) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-66 | 483.39 (19.031) | 16.66 (0.656) | 8.51 (0.335) | 5.28 (0.208) | 31.75 (1.250) | 1.5 (0.06) | - |

| RX-69 | 544.12 (21.422) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1000) | 1.5 (0.06) | - |

| RX-70 | 550.06 (21.656) | 19.84 (0.781) | 10.34 (0.407) | 6.88 (0.271) | 41.28 (1.625) | 2.3 (0.09) | - |

| RX-73 | 596.11 (23.469) | 13.49 (0.531) | 6.68 (0.263) | 5.28 (0.208) | 31.75 (1.250) | 1.5 (0.06) | - |

| 编号 | 环垫外径O.D mm (in.) | 环垫宽度 A mm (in.) | 平面宽度 C mm (in.) | 外斜面高度 D mm (in.) | 环垫高度 H mm (in.) | 八角形环垫半径 R1 mm (in.) | 通孔规格 E mm (in.) |

| RX-74 | 600.86 (23.656) | 19.84 (0.781) | 10.34 (0.407) | 6.88 (0.271) | 41.28 (1.625) | 2.3 (0.09) | - |

| RX-82 | 67.87 (2.672) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | 1.5 (0.06) |

| RX-84 | 74.22 (2.922) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | 1.5 (0.06) |

| RX-85 | 90.09 (3.547) | 13.49 (0.531) | 6.68 (0.263) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | 1.5 (0.06) |

| RX-86 | 103.58 (4.078) | 15.09 (0.594) | 8.51 (0.335) | 4.78 (0.188) | 28.58 (1.125) | 1.5 (0.06) | 2.3 (0.09) |

| RX-87 | 113.11 (4.453) | 15.09 (0.594) | 8.51 (0.335) | 4.78 (0.188) | 28.58 (1.125) | 1.5 (0.06) | 2.3 (0.09) |

| RX-88 | 139.29 (5.484) | 17.48 (0.688) | 10.34 (0.407) | 5.28 (0.208) | 31.75 (1.250) | 1.5 (0.06) | 3.0 (0.12) |

| RX-89 | 129.77 (5.109) | 18.26 (0.719) | 10.34 (0.407) | 5.28 (0.208) | 31.75 (1.250) | 1.5 (0.06) | 3.0 (0.12) |

| RX-90 | 174.63 (6.875) | 19.84 (0.781) | 12.17 (0.479) | 7.42 (0.292) | 44.45 (1.750) | 2.3 (0.09) | 3.0 (0.12) |

| RX-91 | 286.94 (11.297) | 30.18 (1.188) | 19.81 (0.780) | 7.54 (0.297) | 45.24 (1.781) | 2.3 (0.09) | 3.0 (0.12) |

| RX-99 | 245.67 (9.672) | 11.91 (0.469) | 6.45 (0.254) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

| RX-201 | 51.46 (2.026) | 5.74 (0.226) | 3.20 (0.126) | 1.45 (0.057) | 11.30 (0.445) | 0.5 (0.02) | - |

| RX-205 | 62.31 (2.453) | 5.56 (0.219) | 3.05 (0.120) | 1.83 (0.072) | 11.10 (0.437) | 0.5 (0.02) | - |

| RX-210 | 97.64 (3.844) | 9.53 (0.375) | 5.41 (0.213) | 3.18 (0.125) | 19.05 (0.750) | 0.8 (0.03) | - |

| RX-215 | 140.89 (5.547) | 11.91 (0.469) | 5.33 (0.210) | 4.24 (0.167) | 25.40 (1.000) | 1.5 (0.06) | - |

23度= 角度,±0~30′(±1/2度)

A=环垫宽度,+0.20 mm,-0.00 mm(+0.008 in.,-0 in.),在此公差范围内的任何环垫,整个圆周上的宽度变化不得超过0.10mm(0.004 in.)。

C=平面宽度,+0.15mm,-0.00 mm(+0.006 in.,-0 in.);

D=外斜面高度,+0.0 mm,-0.76mm(+0 in.,-0.030 in.);

E=通孔规格,±0.5mm(±0.02.);

H=环垫高度,+0.20 mm,-0.00 mm(+0.008 in.,-0 in.),在此公差范围内的任何环垫,整个圆周上的高度变化不得超过0.10 mm(0.004 in.)。

O.D.=环垫外径,+0.51mm,-0.00 mm(+0.020 in.,-0 in.);

R₁= 环垫半径,±0.5mm(±0.02 in.)

| 编号 | 尺寸mm (in.) | 环垫外径 O.D mm (in.) | 环垫高度 H mm (in.) | 环垫宽度 A mm (in.) | 平面外径0.D.T mm (in.) | 平面宽度 C mm (in.) | 通孔规格E mm (in.) |

| BX-150 | 43 (1-11/6) | 72.19 (2.842) | 9.30 (0.366) | 9.30 (0.366) | 70.87 (2.790) | 7.98 (0.314) | 1.5 (0.06) |

| BX-151 | 46 (1-13/6) | 76.40 (3.008) | 9.63 (0.379) | 9.63 (0.379) | 75.03 (2.954) | 8.26 (0.325) | 1.5 (0.06) |

| BX-152 | 52 (2-1/16) | 84.68 (3.334) | 10.24 (0.403) | 10.24 (0.403) | 83.24 (3.277) | 8.79 (0.346) | 1.5 (0.06) |

| BX-153 | 65 (2-9/16) | 100.94 (3.974) | 11.38 (0.448) | 11.38 (0.448) | 99.31 (3.910) | 9.78 (0.385) | 1.5 (0.06) |

| BX-154 | 78 (3-1/16) | 116.84 (4.600) | 12.40 (0.488) | 12.40 (0.488) | 115.09 (4.531) | 10.64 (0.419) | 1.5 (0.06) |

| BX-155 | 103 (4-1/16) | 147.96 (5.825) | 14.22 (0.560) | 14.22 (0.560) | 145.95 (5.746) | 12.22 (0.481) | 1.5 (0.06) |

| BX-156 | 179 (7-1/16) | 237.92 (9.367) | 18.62 (0.733) | 18.62 (0.733) | 235.28 (9.263) | 15.98 (0.629) | 3.0 (0.12) |

| BX-157 | 229 (9) | 294.46 (11.593) | 20.98 (0.826) | 20.98 (0.826) | 291.49 (11.476) | 18.01 (0.709) | 3.0 (0.12) |

| BX-158 | 279 (11) | 352.04 (13.860) | 23.14 (0.911) | 23.14 (0.911) | 348.77 (13.731) | 19.86 (0.782) | 3.0 (0.12) |

| BX-159 | 346 (13-5/8) | 426.72 (16.800) | 25.70 (1.012) | 25.70 (1.012) | 423.09 (16.657) | 22.07 (0.869) | 3.0 (0.12) |

| BX-160 | 346 (13-5/8) | 402.59 (15.850) | 23.83 (0.938) | 13.74 (0.541) | 399.21 (15.717) | 10.36 (0.408) | 3.0 (0.12) |

| BX-161 | 422 (16-5/8) | 491.41 (19.347) | 28.07 (1.105) | 16.21 (0.638) | 487.45 (19.191) | 12.24 (0.482) | 3.0 (0.12) |

| BX-162 | 422 (16-5/8) | 475.49 (18.720) | 14.22 (0.560) | 14.22 (0.560) | 473.48 (18.641) | 12.22 (0.481) | 1.5 (0.06) |

| BX-163 | 476 (18-3/4) | 556.16 (21.896) | 30.10 (1.185) | 17.37 (0.684) | 551.89 (21.728) | 13.11 (0.516) | 3.0 (0.12) |

| BX-164 | 476 (18-3/4) | 570.56 (22.463) | 30.10 (1.185) | 24.59 (0.968) | 566.29 (22.295) | 20.32 (0.800) | 3.0 (0.12) |

| BX-165 | 540 (21-1/4) | 624.71 (24.595) | 32.03 (1.261) | 18.49 (0.728) | 620.19 (24.417) | 13.97 (0.550) | 3.0 (0.12) |

| BX-166 | 540 (21-1/4) | 640.03 (25.198) | 32.03 (1.261) | 26.14 (1.029) | 635.51 (25.020) | 21.62 (0.851) | 3.0 (0.12) |

| BX-167 | 680 (26-3/4) | 759.36 (29.896) | 35.86 (1.412) | 13.11 (0.516) | 754.28 (29.696) | 8.03 (0.316) | 1.5 (0.06) |

| BX-168 | 680 (26-3/4) | 765.25 (30.128) | 35.86 (1.412) | 16.05 (0.632) | 760.17 (29.928) | 10.97 (0.432) | 1.5 (0.06) |

| BX-169 | 130 (5-1/8) | 173.51 (6.831) | 15.85 (0.624) | 12.93 (0.509) | 171.27 (6.743) | 10.69 (0.421) | 1.5 (0.06) |

| BX-170 | 168 (6-5/8) | 218.03 (8.584) | 14.22 (0.560) | 14.22 (0.560) | 216.03 (8.505) | 12.22 (0.481) | 1.5 (0.06) |

| BX-171 | 218 (8-9/16) | 267.44 (10.529) | 14.22 (0.560) | 14.22 (0.560) | 265.43 (10.450) | 12.22 (0.481) | 1.5 (0.06) |

| BX-172 | 283 (11-5/32) | 333.07 (13.113) | 14.22 (0.560) | 14.22 (0.560) | 331.06 (13.034) | 12.22 (0.481) | 1.5 (0.06) |

| BX-303 | 762 (30) | 852.75 (33.573) | 37.95 (1.494) | 16.97 (0.668) | 847.37 (33.361) | 11.61 (0.457) | 1.5 (0.06) |

23度=角,±0度15分(±1/4度);

A=环垫宽度,+0.20mm,-0.00mm (+0.008in.-0in.),在此公差范围内的任何环垫,整个圆周上的宽度变化不得超过0.10mm(0.004in.);

C=平面宽度,+0.15mm,-0.00mm(+0.006in,-0in.);

D=通孔规格,±0.5mm(±0.02.);

H=环垫高度,+0.20mm,-0.00mm(+0.008in.-0in.),在此公差范围内的任何环垫,整个圆周上的高度变化不得超过0.10mm(0.004in.);

O.D.= 环垫外径,+0.00 mm,-0.15 mm(+0 in.,-0.005 in.);

O.D.T.= 平面外径,±0.05 mm(±0.002 in.)。

结构:用软金属(如铜、铝、软钢、不锈钢)将非金属填充材料(如石墨、陶瓷纤维板)完全包裹覆盖成型。

适用法兰:可用于突面(RF)、全平面(FF)等多种法兰面。

特点与应用:金属外壳保护内部填充材料免受介质侵蚀和机械损伤,同时提供良好的回弹性。常用于热交换器、阀盖及某些腐蚀性介质环境。

ASME B16.20标准对垫片尺寸的规定极为严格。例如:

对于缠绕垫片,标准规定了与不同压力等级(Class)、不同公称尺寸(NPS)法兰匹配的垫片内径(ID)、外径(OD)及基本厚度。

对于环垫片,严格规定了环的宽度、高度、内外径以及关键的截面形状尺寸(如八角形的对角线距离)。

公差范围被严格控制,以确保垫片能准确放入法兰的密封槽或定位在法兰面上,避免因尺寸偏差导致安装不当、压偏或密封比压不足,从而引发泄漏。

法兰密封是一个由“法兰-螺栓-垫片”共同构成的密封系统。法兰垫片在其中起到了关键作用:

初始密封:在螺栓预紧力作用下,垫片发生弹性或塑性变形,填充法兰密封面的微观不平处,形成初始密封。

操作密封:当管道承受内压、温度变化等因素影响,使法兰有分离趋势时,法兰垫片可以依靠残余压紧力和自身的回弹能力,维持足够的密封比压,防止介质泄漏。

补偿作用:法兰垫片可以补偿因温度波动、机械振动或法兰轻微错位带来的间隙变化。

因此,一个选择正确、质量合格、安装得当的ASME B16.20法兰垫片,是整个法兰连接密封性能的最重要保障。

基于ASME B16.20标准的法兰垫片,其应用范围涉及标准法兰连接的工业领域:

石油与天然气:上游开采、炼油、长输管线。

化工与石化:各类反应器、塔器、换热器、工艺管道。

电力工业:火电厂的蒸汽系统、核电厂的辅助系统。

船舶制造:船舶动力系统和管路。

其他工业:造纸、制药、食品加工等行业的特种介质管路。

在选择ASME B16.20法兰垫片时,务必根据法兰类型、介质特性、温度压力参数以及工况特点,结合标准指引做出最适宜的选择。

上海著诚管件制造有限公司作为一家专业的工程制造服务商,在工业管道领域深耕多年,集加工制造、定制服务与销售于一体。公司可承接各类工业管道系统装配、预制管段加工、钢结构工程、防护围栏及非标金属构件定制项目。从材料切割、成型、打磨到焊接组装,我们提供一站式加工服务,助力客户缩短供应链、降低成本、提升项目执行效率。

质量把控:严格实施质量控制体系,从原料采购、加工工艺到产品交付,全流程把控产品的质量。

定制服务:我们始终坚持以项目需求为基础,为客户提供弯曲加工、切割成型、表面打磨、坡口处理及专业焊接等加工制造服务。

专业售后:经验丰富的业务团队,为客户提供专业的技术支持及问题解决方案。

上海著诚管件制造有限公司致力于为客户提供从图纸、加工制造再到成品交付的一站式解决方案,欢迎各类工程项目方、承包商及企业客户来电来图咨询,我们将为您提供专业的技术支持与高效的制造服务,期待成为您值得信赖的合作伙伴。

电话:18625862121(微信同号)