浏览数量: 8 作者: 本站编辑 发布时间: 2025-05-22 来源: 本站

2025.4.25,我们的上海老客户向我们发送了一份关于SS904L钢管和管件的询价单,这是不锈钢较为常见的材质,我们很快向客户完成报价,客户在一周后向我们下单。

上海著诚管件制造有限公司是一家专业从事管道及配件生产加工的企业,我们生产的管道及管配件主要应用于化工、石油、天然气,水利、电力、海洋工程等领域。产品主要包括各种尺寸的无缝管、焊管,对焊管件、高压锻制管件及法兰等。材质包括碳钢,不锈钢,合金钢,低温钢,双相钢,基合金等。

ITEM | DESCRIPTION | 品名 | 类型 | 尺寸 | 材质 | 标准 | QUANITITY | UNIT | 包装 |

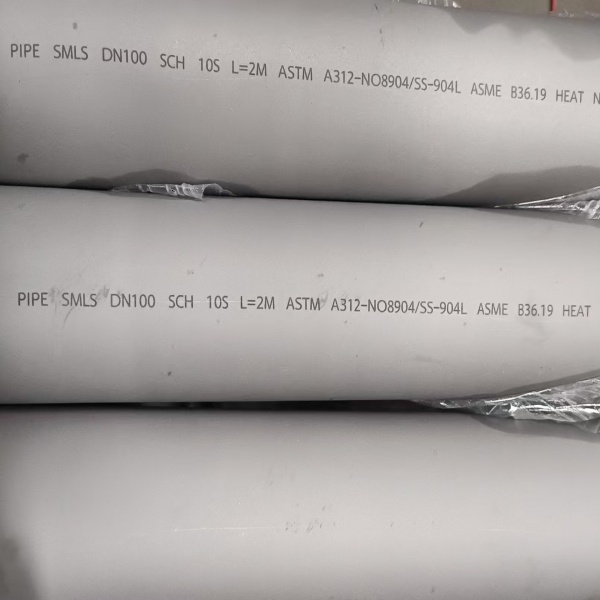

1 | PIPE BE DN100 SCH10S ASTM A312-N08904/SS-904L SMLS ASME B36.19 L=2M | 钢管 | 无缝 | DN100 SCH10S | A312-N08904/SS-904L | B36.19 | 24 | 支 | 木箱 |

2 | ELBOW 90° LR BW SMLS ASTM A403-N08904/SS904L DN100 SCH10S ASME B16.9 | 90°弯头LR | 无缝 | DN100 SCH10S | A403-N08904/SS904L | ASME B16.9 | 15 | 个 | 木箱 |

3 | REDUCER CONCENTRIC DN125 X DN100 SCH10S ASTM A403-N08904/SS904L SMLS ASME B16.9 | 同心大小头 | 无缝 | DN125 X DN100 SCH10S | A403-N08904/SS904L | ASME B16.9 | 15 | 个 | 木箱 |

外径(Outer Diameter, OD)

目的:确保钢管的外径符合设计要求,影响与其他管道或设备的连接。

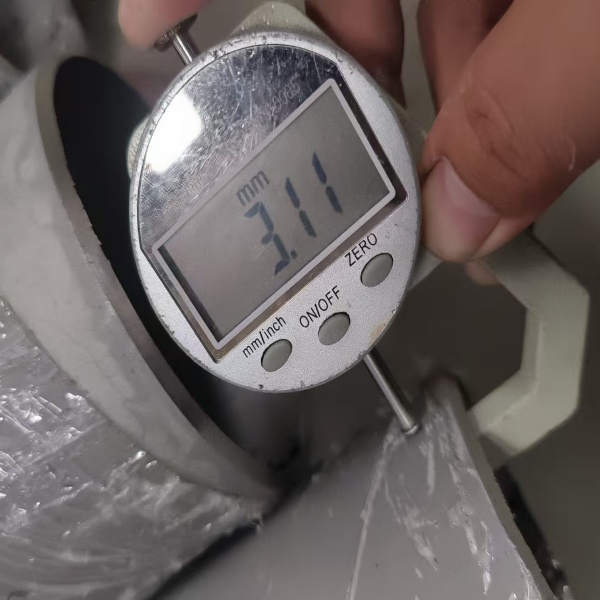

壁厚(Wall Thickness, WT)

目的:影响钢管的承压能力和使用寿命。

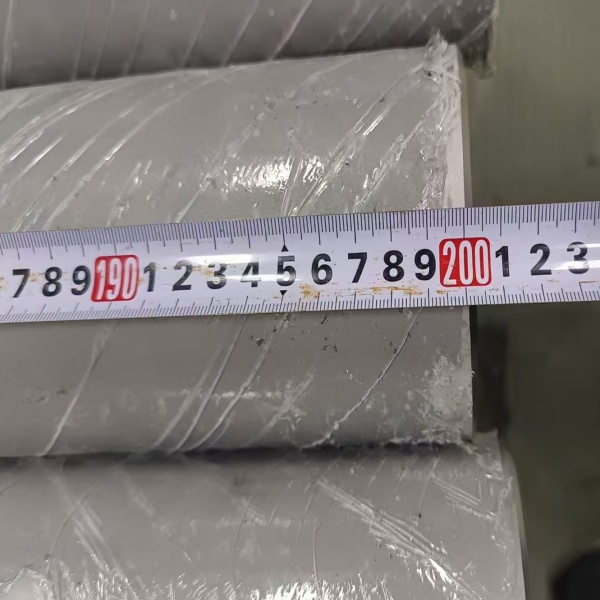

长度(Length)

目的:确保钢管的长度符合定尺、倍尺或通常长度要求。

外径 (OD):测量管件两端的外径,确保符合公差。

壁厚 (WT):在管件各部位(尤其是弯头的外弧和内弧、大小头的过渡段)进行测量,确保壁厚在允许偏差范围内。

CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

ASTM A403 WP904L | MIN | 23.00 | 19.00 | 4.000 | |||||

MAX | 0.02 | 2.00 | 0.045 | 0.035 | 1.00 | 28.00 | 23.00 | 5.000 |

MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

ASTM A403 WP904L | 490 min | 220 min | 28 min |

CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

ASTM A312 TP904L | MIN | 23.00 | 19.00 | 4.00 | ||||||

MAX | 0.020 | 2.00 | 0.045 | 0.04 | 1.00 | 28.00 | 23.00 | 5.00 | 0.10 |

MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

ASTM A312 TP904L | 490min | 215min | 35min |

TABLE X1.1 Dimensions of Welded and Seamless Stainless Steel Pipe | ||||||||||

NPS | Outside Diameter | Nominal Wall Thickness | ||||||||

Designator | in. | mm | Schedule 5SA | Schedule 10SA | Schedule 40S | Schedule 80S | ||||

in. | mm | in. | mm | in. | mm | in. | mm | |||

1/8 | 0.405 | 10.29 | 0.049 | 1.24 | 0.068 | 1.73 | 0.095 | 2.41 | ||

1/4 | 0.540 | 13.72 | 0.065 | 1.65 | 0.088 | 2.24 | 0.119 | 3.02 | ||

3/8 | 0.675 | 17.15 | 0.065 | 1.65 | 0.091 | 2.31 | 0.126 | 3.20 | ||

1/2 | 0.840 | 21.34 | 0.065 | 1.65 | 0.083 | 2.11 | 0.109 | 2.77 | 0.147 | 3.73 |

3/4 | 1.050 | 26.67 | 0.065 | 1.65 | 0.083 | 2.11 | 0.113 | 2.87 | 0.154 | 3.91 |

1 | 1.315 | 33.40 | 0.065 | 1.65 | 0.109 | 2.77 | 0.133 | 3.38 | 0.179 | 4.55 |

1 1/4 | 1.660 | 42.16 | 0.065 | 1.65 | 0.109 | 2.77 | 0.140 | 3.56 | 0.191 | 4.85 |

1 1/2 | 1.900 | 48.26 | 0.065 | 1.65 | 0.109 | 2.77 | 0.145 | 3.68 | 0.200 | 5.08 |

2 | 2.375 | 60.33 | 0.065 | 1.65 | 0.100 | 2.77 | 0.154 | 3.91 | 0.218 | 5.54 |

2 1/2 | 2.875 | 73.03 | 0.083 | 2.11 | 0.120 | 3.05 | 0.203 | 5.16 | 0.276 | 7.01 |

3 | 3.500 | 88.90 | 0.083 | 2.11 | 0.120 | 3.05 | 0.216 | 5.49 | 0.300 | 7.62 |

4 | 4.000 | 101.60 | 0.083 | 2.11 | 0.120 | 3.05 | 0.226 | 5.74 | 0.318 | 8.08 |

4 | 4.500 | 114.30 | 0.083 | 2.11 | 0.120 | 3.05 | 0.237 | 6.02 | 0.337 | 8.56 |

5 | 5.563 | 141.30 | 0.109 | 2.77 | 0.134 | 3.40 | 0.258 | 6.55 | 0.375 | 9.52 |

6 | 6.625 | 168.28 | 0.109 | 2.77 | 0.134 | 3.40 | 0.280 | 7.11 | 0.432 | 10.97 |

8 | 8.625 | 219.08 | 0.109 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 | 0.500 | 12.70 |

10 | 10.750 | 273.05 | 0.134 | 3.40 | 0.165 | 4.19 | 0.365 | 9.27 | 0.500B | 12.70B |

12 | 12.750 | 323.85 | 0.156 | 3.96 | 0.180 | 4.57 | 0.375B | 9.52B | 0.500B | 12.70B |

对焊管件的公差 | |||||||||||||

公称尺寸 Nominal Size | 所有管件1)2) | 45°、90° 弯头、三通、四通 |

| 180 " 弯头 | 管帽 | 异径管 、翻边短节 | 翻边短节 | ||||||

DN | NPS | OD 3) 4) | ID 3) | A B C M | A B |

| K | U | E, E1 | H F |

| R | t |

15-65 | 1/2 -21/2 | +1.6 | ± 0.8 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 | 0 | +1.6 |

80-90 | 3-31/2 | ± 1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 | 0 | +1.6 |

100 | 4 | ± 1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 | 0 | +1.6 |

125-200 | 5-8 | +2.4 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 6 | ± 2 | 0 | 0 | +1.6 |

250-450 | 10-18 | +4.0 | ± 3.2 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 | ± 6 | ± 2 | 0 | 0 | +3.2 |

500-600 | 20-24 | +6.4 | ± 4.8 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 | ± 6 | ± 2 | 0 | 0 | +3.2 |

650-750 | 26-30 | +6.4 | ± 4.8 | ± 3 | ± 6 | --- | --- | --- | ± 10 | ± 5 | --- | --- | --- |

800-1200 | 32-48 | +6.4 | ± 4.8 | ± 5 | ± 6 | --- | --- | --- | ± 10 | ± 5 | --- | --- | --- |

1300-1500 | 52-60 | +6.4 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

1600-1700 | 64-68 | +6.4 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

1800-2000 | 72-80 | +6.4 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

制药工业: 对清洁度和耐腐蚀性要求极高的管道系统。

纸浆和造纸工业: 在漂白槽以及其他暴露于硫酸盐和氯化物等腐蚀性化学品的设备中。

海水冷却设备: 由于其在海洋环境中卓越的抗氯化物点蚀和缝隙腐蚀能力。

烟气脱硫装置 (FGD): 用于处理腐蚀性烟气的污染控制设备。

化肥生产: 特别是在磷酸生产中。

电力行业: 在某些对耐腐蚀性有高要求的换热器和系统中。